FROM DREAM TO REALITY

از رویا تا تحقق

راهکارهای روشنایی برای ارتقای کیفیت زندگی

شرکت روشنایی جواهرنور با تعهدی راسخ به دنبال خلق فضایی منحصربهفرد است که کیفیت زندگی در شهرها و مناطق مسکونی را از طریق کشف جنبههای گوناگون روشنایی ارتقا دهد. این شرکت بر آن است تا رفاه و ایمنی همه کاربران در فضاهای عمومی را تضمین کند و جایگاه پیشرو جواهرنور همیشه به واسطه سرمایهگذاری مستمر در نوآوری، خلاقیت و کیفیت قرار گرفته که نتیجه این تعهد، تولید محصولات انحصاری، مقاوم و مقرونبهصرفهای است که در تمام حوزههای فعالیت این شرکت عرضه میشوند .�تنوع محصولات جواهرنور شامل پایه چراغهای روشنایی برای خیابانها، جادهها، مسیرهای پیادهروی، پارکها ، باغها، مناطق تفریحی، فضاهای معماری و تاریخی ، زمینهای ورزشی ، پارکینگها و محصولات مبلمان شهری و غیره می باشد .

این شرکت در طول بیش از دو دهه فعالیت و تجربه ، به انتخابی مطمئن برای معماران، طراحان، �شهرداریها، مهندسان و پیمانکاران تبدیل شدهاست که زیباسازی محیط زندگی در روز و شب و تضمین ایمنی محیط از ویژگیهای برجسته شرکت جواهرنور می باشد .هدف ما ارائه راهکارهای جامع روشنایی و همسو با بهبود کیفیت زندگی ، در جوامعی که به آن خدمت میکنیم، می باشد و متعهد به تولید و ارائه محصولاتی با کیفیت بالا می باشیم ، تا روشنایی بخش مسیر شما باشد و به همین منظور، از پیشرفتهترین فناوریها برای توسعه راهکارهای انحصاری و نوآورانه روشنایی استفاده کرده ایم تا بتوانیم با ترکیب کارایی و انعطافپذیری، هویت فرهنگی و شهری را به شکلی زیبا منعکس نماییم و حداکثر راحتی بصری را برای هر فضایی فراهم آوریم و همچنین با افتخار از فناوریهای دوستدار محیط زیست حمایت و همواره تلاش نموده تا محصولاتی را با هدف جلب حداکثری رضایتمندی مشتریان و افزایش زیبایی شهری ارائه نماییم.

مزایای محصولات شرکت جواهرنور

-ارائه طیف گستردهای از مدلها و ارتفاعها برای پاسخگویی به نیازهای مختلف روشنایی.

-طیف گستردهای از پوششهای حفاظتی با کیفیت.

-ارائه محصولات مقاوم، پایدار و مهندسیشده.

-طراحی نوآورانه و سفارشی برای هماهنگی بصری با محیط و حفظ فرهنگ و هویت محلی .

-پاسخگویی و خدمات قبل و پس از فروش به صورت 24 ساعته.

-محصولاتی مقاوم در برابر خوردگی و بدون نیاز به نگهداری.

-نصب سریع وآسان و هزینههای مونتاژ پایین.

-افزایش احساس امنیت در جادهها و معابر .

-اهمیت به رونق کسبوکار و گردشگری.

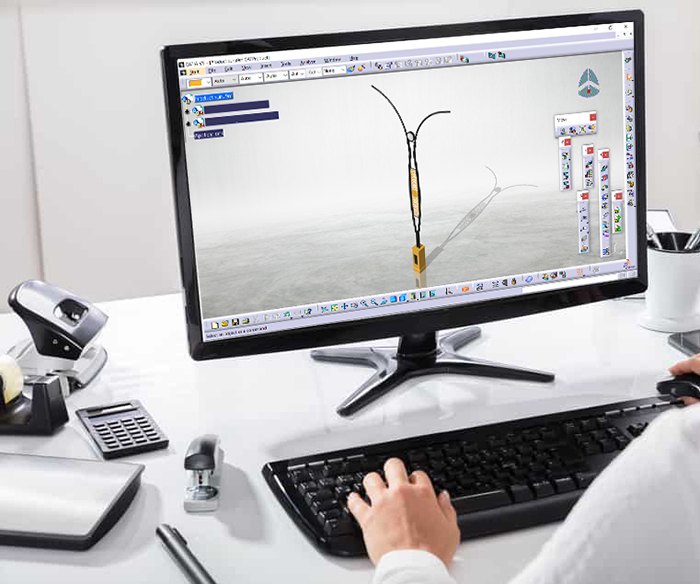

طراحی و خلاقیت

شرکت جواهرنور با داشتن واحدهای تحقیق و توسعه – فنی و مهندسی ، با ارائه خدمات طراحی محصولات سفارشی و مناسب برای هر کاربرد ، تجربه و توانایی قوی در ادغام نوآوریهای�پیشرفته ، اصول مهندسی دقیق و ایمنی بالا و کیفیت تضمین شده در تولید محصولات �همیشه موثرترین و خلاقانهترین راهکارها را ارائه نموده تا با توانایی تولید محصولات برای� پروژههای کوچک تا کلان باعث افزایش هماهنگی و جذابیت بصری محیط و رضایتمندی مشتریان خود باشد و تا کنون به سبب پروژه های اجرا شده در داخل و خارج از کشور ، و ایجاد رضایت مشتریان ، به خود افتخار می نماید .

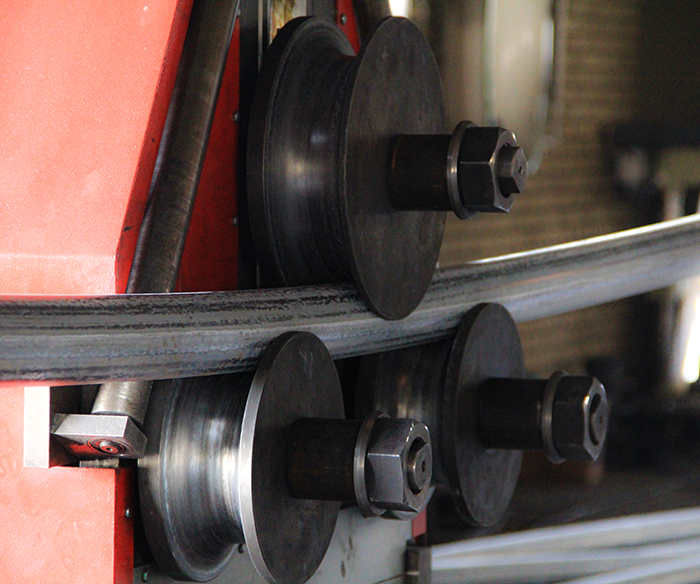

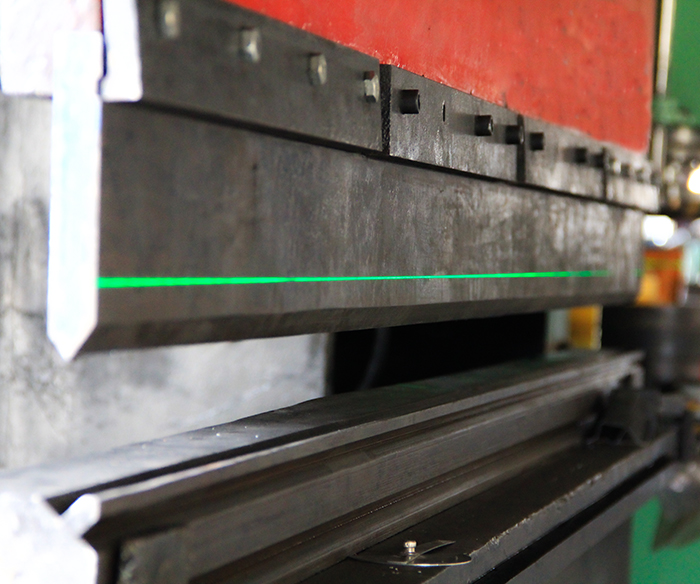

ما با درک اهمیت بالای یک واحد تولیدی پیشرفته همیشه تلاش کرده ایم تا از جدیدترین�فناوریها استفاده نماییم که اکنون دارای مراحل تولید پیشرفته ای شامل دستگاه تولید مقاطع لوله کپسولی (بیضی) ، دستگاه اتومات پرس مقاطع لوله پایه های خیابانی و بزرگراهی و مدوّر ، برش سی ان سی لیزر و پلاسما، جوشکاری Co2 با دقت بالا، سیستم پرداخت توسط سندبلاست ، خطوط رنگ ، قالبهای متنوع فرمینگ فولادی ، قالبهای تزریق آلومینیوم و تزریق پلاستیک می باشیم که تمامی فرآیندها مطابق با بالاترین استانداردهای جهانی انجام میشوند.

مواد و تولید

شرکت جواهرنور برای اطمینان از کیفیت، از موادی استفاده میکند که آزمایش شدهاند و فرآیند تولید نیز مطابق استانداردهای زیر انجام میشود:

-لوله و پروفیل های فولادی با گرید ST37 مطابق با استاندارد DIN17100 و ISO 9330-4:2000

-بیس پلیت از ورق فولادی با گرید ST37 مطابق با استاندارد DIN17100 و ISO 4995:1991

-قطعات آلومینیومی مطابق با سری 2-755 BS EN

-قطعات دکوراتیو از ورق فولادی با گرید ST12 مطابق با استاندارد DIN17100 و ISO 4995:1991

-فرآیند جوشکاری طبق استاندارد AWS D1.1 و نشریه 228

-گالوانیزاسیون گرم طبق استاندارد ASTM A123

-فرآیند پاکسازی توسط سندبلاست طبق استاندارد 1-8501 ISO

-طراحی محصولات طبق استانداردهای نشریه 195 و 614 و استاندارد ASCE07

-پوشش حفاظتی و رنگ بر اساس استاندارد طبقه بندی شرایط اقلیمی 2:2017 – 12944 ISO

پوشش حفاظتی

انواع پوشش های حفاظتی و رنگ با توجه به شرایط اقلیمی در محصولات جواهرنور شامل :

1- پوشش رنگ پودری الکترواستاتیک مقاوم در برابر ضربه و اشعه UV با ضخامت� تقریبی 80میکرون و ضمانت حفظ کیفیت تا 2 سال در محیط های شهری

2- پوشش رنگ مایع پلیاورتان دو جزئی شامل لایه آستر زینک ریچ اپوکسی دو جزیی (گالوانیزه سرد) � و لایه نهایی پلی اورتان دو جزیی با ضخامت نهایی 120 میکرون مقاوم در برابر اشعه UV و� محیطهای خورنده با رطوبت بالا و ضمانت حفظ کیفیت تا 5 سال

3-پوشش گالوانیزه گرم: با ضخامت تقریبی 80 میکرون و ضمانت حفظ کیفیت تا 10 سال

4- ترکیب پوشش گالوانیزه گرم به عنوان لایه اول (80میکرون) و لایه نهایی پوشش رنگ � پودری الکترواستاتیک (80 میکرون) و ضمانت حفظ کیفیت تا 3 سال

5- ترکیب پوشش گالوانیزه گرم به عنوان لایه اول (80میکرون) و لایه نهایی پوشش � پلیاورتان دو جزئی (100 میکرون) و ضمانت حفظ کیفیت تا 3 سال

شرکت جواهرنور همیشه تاکید بر استفاده از فرآیندهای سازگار با محیط زیست را دارد و از مواد شیمیایی مضر در فرآیندها اجتناب کرده و فرآیندهایی مانند سندبلاست و پوشش رنگ را با رعایت استانداردهای زیست محیطی اجرا می نماید و همیشه تلاش نموده تا سفارشهای مشتریان را به شیوهای مسئولانه و دوستدار محیط زیست ارسال نموده و همواره به دنبال راهکارهای نوآورانه برای کاهش اثرات زیستمحیطی در بستهبندی می باشد.

ارزشهای سازمانی شرکت جواهرنور

-نوآوری : پیشرفت در گرو نوآوری است و ما همواره به دنبال تغییر و تحول درصنعت روشنایی هستیم.

-صداقت : شفافیت و تعهد به اصول اخلاقی، پایههای اصلی سازمان را تشکیل میدهند.

-کیفیت : کیفیت بالای محصولات و فرآیندها باعث رضایتمندی بالای مشتریان می گردد.

-اشتیاق : عشق به کار، محرک پیشرفت ما در هر بخش از سازمان است.

-روابط : ایجاد روابط پایدار با مشتریان و همکاران ، هدف اصلی ما در هر تعامل است.

مسئولیت های اجتماعی شرکت جواهرنور

ما با رویکردی مسئولانه، اقدامات زیر را برای توسعه پایدار انجام دادهایم:

-بازیافت مواد و کاهش استفاده از پلاستیک در فرآیندهای تولید و بسته بندی.

-تمهیدات کاهش مصرف انرژی شامل برق ، گاز و آب و اجرای سیستمهای کم مصرف در فرآیند تولید.

-ارائه کمک هزینه های آموزشی به نیروهای تازه وارد .

ما معتقدیم که تنها روشنایی بهتر کافی نیست؛ باید به آیندهای پایدارتر بیاندیشیم و� در هر قدم برای ساخت جهانی بهتر تلاش کنیم.

Lighting Solutions for a better quality of life

Javahernoor has a passion to create a distinctive atmosphere that improves the quality of life in the cities and towns by exploring the many potential facets of lighting, that supports the well being and safety of all users in public space. Our leading position is supported by the commitment to invest continuously in innovation, creativity and quality to improve our organization and processes. This commitment results in new exclusively designed, sustainable, cost effective products in each business area we are operating.

This allows us to provide the market with complete lighting solutions that are in line with our mission of improving the quantity of life in the communities that we serve.

Ever since our establishment , we have been committed to manufacture and deliver a range of high-quality luminaires and lighting poles that light your way.

To do so, we use the most advanced technology to develop innovative lighting solutions with exclusive designs.

Javahernoor can stylishly convey the identity of a city with a combination of efficiency and modularity to maximise the visual comfort that is best suited to each specific space.

Over the years, we have become a trusted choice of architects, designers, municipalities, developers, building contractors and engineers for their lighting requirements. Beautifying the living environment by day and by night keeping the environment safe are the hallmarks ofJavahernoor. Our lighting poles are perfect for streets, roads, pedestrian paths, gardens, meeting leisure areas, architectural or landscaped areas, sports grounds, parking lots, etc.

Javahernoor takes immense pride to promote environment friendly technologies and the solutions offered are people centric and designed to enhance the urban beauty.

The Javahernoor Pole’s Advantage:

-Corrosion resistant and Maintenance free.

-Quick installation and low assembly costs.

-A wide range of Pole heights and bracket options to meet various lighting requirements.

-Functionally versatile, strong and stable with sound engineering.

-A wide range of shades available with exceptional finishing options.

-Innovative Design options to provide Visual integration with the environment.

-Increasing the feeling of safety on roads reclaiming the culture of a place.

-Encourage aggregation, stimulating business and tourism.

Javahernoor has an edge of having a design for every application and a reputation of excellence into everything we manufacture.

Our complete range of design and technical specification can be viewed www.javahernoor.com

Technical Characteristics

With over 2 decades of experience and the strong ability to integrate advanced technological� innovation into our pole we are able to offer the most effective and creative solutions. Javahernoor’s pole design, production and finishing processes have several technical characteristics that form the bases of effective design and safety. Innovative Design, World-Class EngineeringDriven by our passion for innovative lighting and with the assistance of a dedicated team of qualified design engineers �integrated with market experience, Javahernoor’s manufacturing program covers a complete range of highly professional Lighting pole products.

Our range of lighting solutions include but are not limited to :

-Street pole lights series

-Garden pole lights series

-Octagonal series

-Bollard series

-Urban Furniture

-Customised design

Our architectural poles are engineered to take a wide range of Luminaries and brackets. Engineering� parameters vary depending upon material, lighting load, type of bracket, tower weight, local soil and environment conditions. Structural design also varies based on terrain category and reference wind speed factor.

Production Process

Fabrication

Javahernoor realizes the significance of an advanced production facility. With our constant focus on quality, we ensure that our production facility is well-equipped with state-of-the-art technology. From Laser and plasma cutting machines to folding and welding of sheets, plates and tubes, every process takes place with utmost precision to deliver you nothing but the best in the world of poles solutions.

Our certified welders use a unique V groove technique to weld pole sections, following a high-end MIG welding process.

In addition, certain design elements require the use of specific processed tools and dies in �manufacturing. From aluminium extrusion to steel forging, cast aluminum, shell moulding and� pressure die casting are performed adhering to the top-quality benchmarks. Once the fabrication� process is completed, our poles move to the sand blasting plant for surface preparation.

Creativity Takes Wings At Javahernoor

Javahernoor is consistently striving to develop complete lighting solutions from designing to finished products to maximize function, while enhancing visual appeal. From bespoke design services, to almost any combination of pole, luminaire and finish Javahernoor can truly build a unique solution for your projects.

To do so we have all the facilities for in-house product development and production capacities from small quantities to mega projects. With Javahernoor, it’s easy to find that perfect pole that seamlessly merges into the setting you want.

Bracket Options

Javahernoor poles can be fitted with single or multi light fixture arms in order to install one or more light sources. Wall mounting options are also available to complete a particulate series.

Our unique demounting bracket construction ensures easier transportation and pole orientation for simple self-assembly and installation.

Materials and Production

In order to ensure quality, Javahernoor uses material that are tested and Production process comply with the following standards.

Material for tubes : Steel of grade ST37

Material for base plate : Steel of grade ST37

Material for Aluminum : BS EN 755-2 series

Material for Steel sheet : Steel of grade ST12

Welding process : AWS D1.1

Hot Dip Galvanization : ASTM A123

Sandblast cleaning : ISO 8501-1 sa 2 1⁄2

Foundation Details

No pole would stand to the test of time without a solid foundation. This is why Javahernoor pays utmost attention to detail when it comes to the surface mounting base plates. The dimensions and thickness of these plates are determined based on topography, condition of the soil, the pole’s design and the wind load. To make sure our lighting poles are not just strong but also highly stable, we provide additional gussets based on dimension and design of the poles. This design gives extra strength to the section around the door area. This solution is stronger as thetension and the effect of torsion is also�reduced. The elongated foundation holes in the base plate are designed in such a way that fine �adjustments / alignment during the pole’s installation can be made quickly. To ensure longevity we�recommend and supply hot dip GI foundation bolts and nuts for high corrosion resistance and �durability.

Finishing Process

The choices of paint coatings as follows:

By relying on in house modern laboratory equipment and high-tech technology, we are set to broaden the customers’ knowledge about deciding on the right corrosion resistant coating system for �protecting metal structures.The stages of surface preparation are carried out in two methods of� chemical purification and air abrasive blasting cleaning by applying air pressure (Sandblast). For paints coatings, surface cleaning is solely performed by air-pressure abrasive blasting.

-The permissible cleaning degree by blasting method is in accordance with ISO 8501-1 and near white metal blast cleaning Sa 2½.

-Polyester Electrostatic Powder coating: the relative resistance to impact and UV radiation with an �approximate thickness is 80 μm.The guarantee period for electrostatic powder coating in urban areas with under moderate corrosion resistance not subject to continuous water spraying is 2 years and for Hammer Electrostatic Powder is up to 1 year.

-Two-component polyurethane coatings: two components epoxy zinc-rich coating and suitable for� corrosive environments with high humidity, UV resistant, approximate thickness of the last layer� (polyurethane) 120 μ, the guarantee period is 5 years.

-system suitable for corrosive environments and industrial areas with high humidity and corrosive�atmosphere, exposed to impact and wear, hot dip galvanized coating, with a thickness of �approximately 70-80 microns, by applying Electrostatic Powder coating or two-component�polyurethane final finish color, the durability of which in these environments is at least 5 years.

Finally, the types of coating you can choose are divided as follows:

1- Electrostatic powder coating

2- Two-component polyurethane coatings

3- Hot dip galvanized coating

4- Hot dip galvanized coating and Electrostatic powder coating

5- Hot dip galvanized coating and Two-component polyurethane coatings

The Environment

Javahernoor’s commitment to the environment needs no introduction. In all our facilities, the �emphasis is on environmentally friendly processes and our sandblasting process is no exception. By eliminating the usage of non-eco-friendly and harsh chemical processes, sand blasting is one of the� critical techniques to ensure the environment’s safety – thanks to no chemical and acid use.Our Powder coating process is also an environmentally friendly, with no volatile organic compounds and no toxic heavy metals used. In addition over sprayed powders can be re-used and re cycled.

Packing

We do everything we can to ship your order in the most environmentally responsible way possible. We are also constantly searching for the most innovative solutions for eco-conscious shipping.